Analog Radio Frequency Telemetry Systems

IR Telemetrics, Inc. engineers, builds, installs, and operates wireless measurement systems that are one of a kind in the world.

- Small and can be packaged in tight places

- Robust and can withstand high loads and temperatures up to 185°C

- Can operate in very harsh environments

- Backed by a 100% guarantee for success on every installation

ADVANCED RADIO TELEMETRY SOLUTIONS – WIRELESS DATA TRANSFER UTILIZING ANALOG RF TELEMETRY

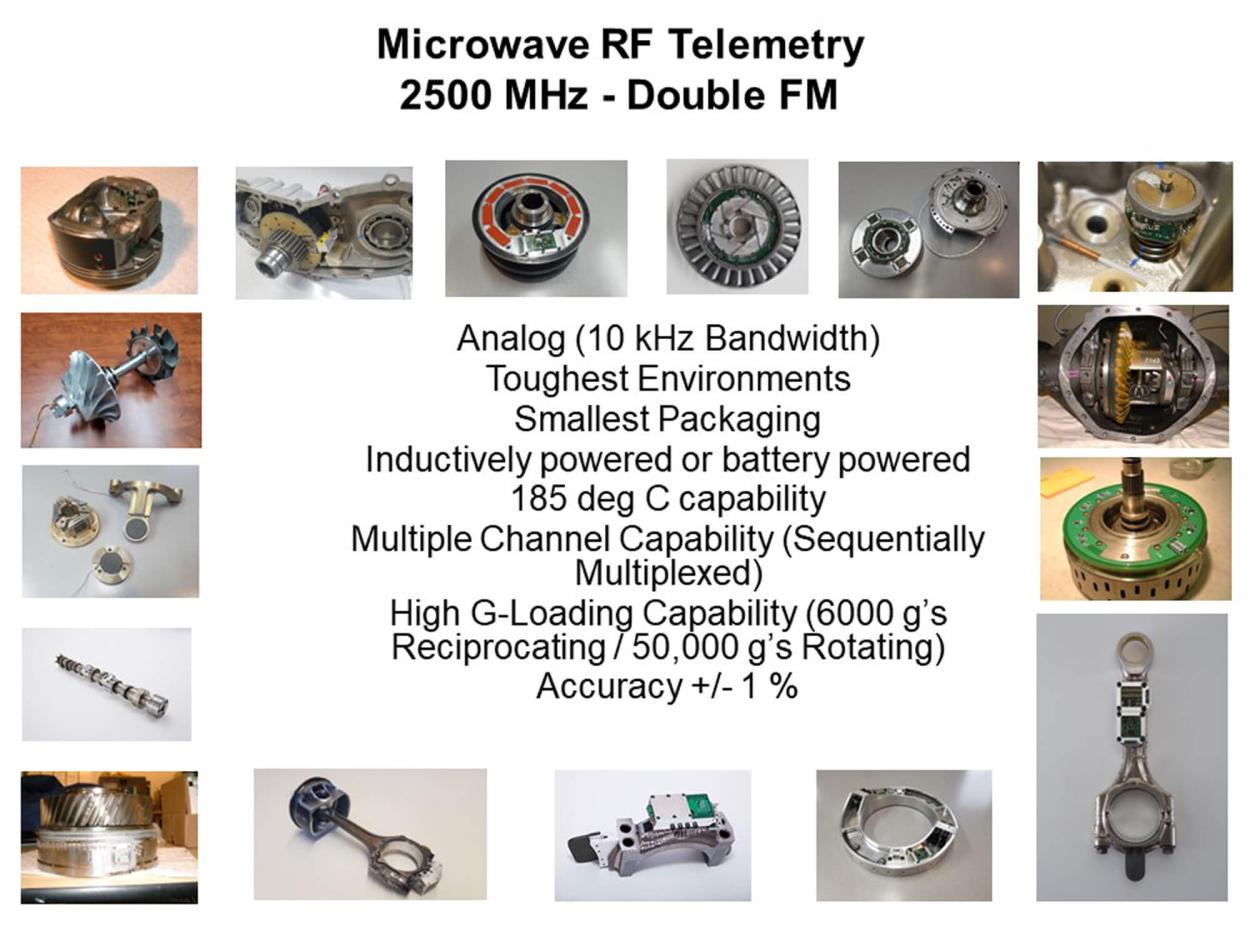

Servicing many industries, IRT custom builds their Radio Telemetry Systems to measure temperature, pressure, proximity, motion, rotation, strain, acceleration, and torque on rotating and reciprocating components.

- Any internal or external engine component

- Any internal transmission, torque converter, or transfer case component

- Any internal gearbox component

- Any gas turbine component

- Any rotating shaft

EXAMPLES OF THE SUCCESSFUL APPLICATION OF ANALOG RF WIRELESS MEASUREMENT SYSTEMS CUSTOM BUILT BY IR TELEMETRICS

- Helicopter Rotor Shaft Torque

- Gas Turbine Shaft Torque

- Turbo Charger Turbine Temperature

- Supercharger Rotor Temperature

- Automatic Transmission Clutch Reaction Plate Temperature

- Automatic Transmission Clutch Pressure

- Wet Clutch Reaction Plate Temperature

- Hybrid Transmission Reaction Plate Temperature

- Transfer Case Reaction Plate Temperature

- Torque Converter Internal Component Pressure, Temperature, Strain and Cavitation

- Valve Temperature and Strain

- Camshaft Torque and VCT Pressure Supply

- Damper Strain

- Dry Clutch Reaction Plate Temperature

- Rear Differential Temperature and Gear Strain

- Driveshaft Torque

- Shaft Torque and Bending

- Piston Embedded Metal Temperature, Dynamic Surface Temperature, and Heat Flux

- Piston Ring Land Pressure and Vertical Ring Motion

- Piston Secondary Motion

- Piston Friction in Cylinder Bore

- Piston Strain

- Piston Pin Strain, Temperature, Rotation and Motion

- Connecting Rod Strain, Bolt Strain, Bearing Temperature, Oil Flow and Pressure-Cavitation

- Compressor Cross Head Temperature

- Marine Prop Shaft, Driveshaft and Propeller Torque

- Large Mining Truck Planetary Gear Temperature

- Locomotive Traction Motor Bearing Cage Strain

- Rotary Cement Kiln Strain

- Rotating Trommel Strain

All these types of applications would utilize IRT’s Analog RF Telemetry system. The microwave transmitter, which is mounted on the component, is powered by an Inductive Power Converter, also mounted on the component. The Power Converter powers the transmitter continuously and is recharged when a component mounted Inductive Pick-up Coil is coupled with a stationary Inductive Exciter Coil.

IRT’s Analog RF Telemetry System uses a Double FM modulation technique. The first modulation produces a very stable square wave running from 10 to 70 kHz. This square wave is used to modulate a microwave carrier that is typically centered at 2500 MHz. This is an analog system with bandwidths on the order of 10 kHz.

IRT has three Microwave Transmitter designs for component applications: 1 channel, 7 channel, and 15 channel. The multi-channel designs utilize sequential multiplexing in which the transmitter sends one channel at a time and sequentially switches between each channel at a specified rate ranging from 0.02 to 30 seconds.

The data transmitted from the component is received by short, (1.5 inch) monopole antennas. The signal is amplified and sent to a Bench Top Receiver. Through a USB connection to a computer, data can then be viewed using our DigFv software. The software has a display through which each data set that is acquired can be viewed showing each channel location on the component real time. The results are immediately exportable to standard text formats for further analysis.

STATE-OF-THE-ART MICROWAVE RECEIVER and DATA ACQUISITION

Our Model 5060 Microwave Receiver and Data Acquisition Unit encompasses many State-of-the-Art features.

Multi Frequency Tuning Capability — The receiver will allow you to tune into multiple frequencies rather than just one. This would allow you to have more than one component instrumented, yet be able to use just one receiver to collect data from all of them.

Auto Tuning — This feature insures you are always tuned into the correct component transmitting frequency.

High Signal to Noise Ratio — More signal/less noise.

Diversity Reception — This feature allows you to install more than one antenna. The receiver will then always look for the antenna receiving the strongest signal at any given time. This will help eliminate signal drop outs during your testing.

Internal Amplifiers — In the receiver design, we have integrated the amplifiers into the receiver which eliminates external connections and the potential to damage the amps during power up or cable connection.

Combined Receiver and Data Acquisition into One Unit — We have combined the two functions of signal reception and data processing into one case. This eliminates some external connections. The design also has true USB 2.0 data streaming.

PROVEN RADIO FREQUENCY TELEMETRY IN ACTION

Each telemetry installation is guaranteed 100% to successfully transmit the desired data for the duration of the testing it was installed for.

- Proven on internal combustion pistons operating as high as 12,000 RPM

- Proven with diesel piston installations operating continuously for 3,000 hours

- Provine on turbochargers spinning at 40,000 RPM

- Provine on Superchargers spinning at 26,000 RPM

- Provine on gas turbines spinning at 25,000 RPM

- Provine at temperatures as high as 185°C

Contact Us for Reliable Wireless Telemetry Solutions Today

If you require accurate data transmission of up to 15 channels from the most extreme environments, contact our applications engineering staff for a no-cost review of your needs and learn how IRT can help you:

- Reduce Product Development Lead Times

- Enhance The Design of Machine Components

- Understand Component Failures and Eliminate Them

- Expand and Enhance R&D Capabilities

Are you curious about the future of automatic transmission development? Explore our latest blog post about advancements in wireless measurement systems that are shaping the automotive industry!