Trend towards increased number of gears in automatic transmissions.

In order to keep an engine operating at an rpm range which has the best torque (power) and fuel efficiency, transmission manufacturers are stepping up the number of gears used in their automatic transmissions. Using multiple gears with a smaller ratio between gears results in smoother and quieter acceleration, and can increase fuel economy depending on other drivetrain factors such as vehicle size, engine size, and drive axle ratios. It also results in reduced C02 emissions.

In the development of these complex transmissions, engineers need to understand the shaft torques, the fluid pressures activating the clutches, and reaction plate temperatures within each of the clutches. Since the clutches are activated with fluid pressure, this is perhaps one of the most critical measurements.

IR Telemetrics wireless transmitters for small spaces

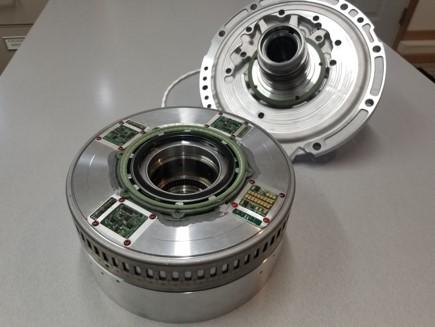

IR Telemetrics, Inc., the world leader in custom built wireless measurement systems, has helped OEMs in several applications by providing systems which can be packaged in extremely tight spaces, operate in high fluid temperatures and pressures, and withstand high inertial loading.

Working with their customers engineering staff, with extensive use of CAD models, IRT’s designers are very successful in packing all the components of their inductively powered wireless transmitter into very small areas inside the transmission. As many as 10 inductively powered wireless measurement systems have been custom designed and installed in a single automatic transmission to measure reaction plate temperatures, fluid pressures and shaft torques on multiple clutches simultaneously. This is accomplished by having each transmitter, transmitting at a unique frequency and its corresponding receiver set up to tune into that unique frequency. It is analogous to having multiple radio stations playing at the same time inside the transmission housing, each playing a different song.

In addition, the design challenge extends to the stationary components, like the transmission housing, where inductive power coils must be designed, built, and installed to power the transmitters, which are mounted on the rotating components, along with multiple antennas to receive the real time data.

No matter how complex an assembly may be, IR Telemetrics can design and install a custom wireless measurement system to transmit data from any internal rotating or reciprocating machinery component.

For years their moto has been: Wireless Data Transfer… For any Component…For any Transducer Type… In Any Environment…100% Guaranteed!

Contact IR Telemetrics to learn more.