Transducer development driven by customer need for new measurement capabilities

The design of the piston pin bore, the piston pin, and the small end of the connecting rod which the pin passes through, are all interrelated. In a floating pin design, the pin rotates freely within the rod and the pin bore. This prevents excessive wear on the pin in one location, and spreads the wear on the pin around the entire circumference of the pin surface, dramatically increasing its service life.

There are multiple factors which can affect pin rotation. Piston temperature, pin temperature, rod/bearing temperature, and oil flow up through the rod for lubrication. Traditionally, extensive durability testing on an engine dynamometer, followed by tearing down the engine afterwards to inspect the individual components, especially the piston pin, was the only indicator for engineers to determine if the pin was rotating as it was designed too.

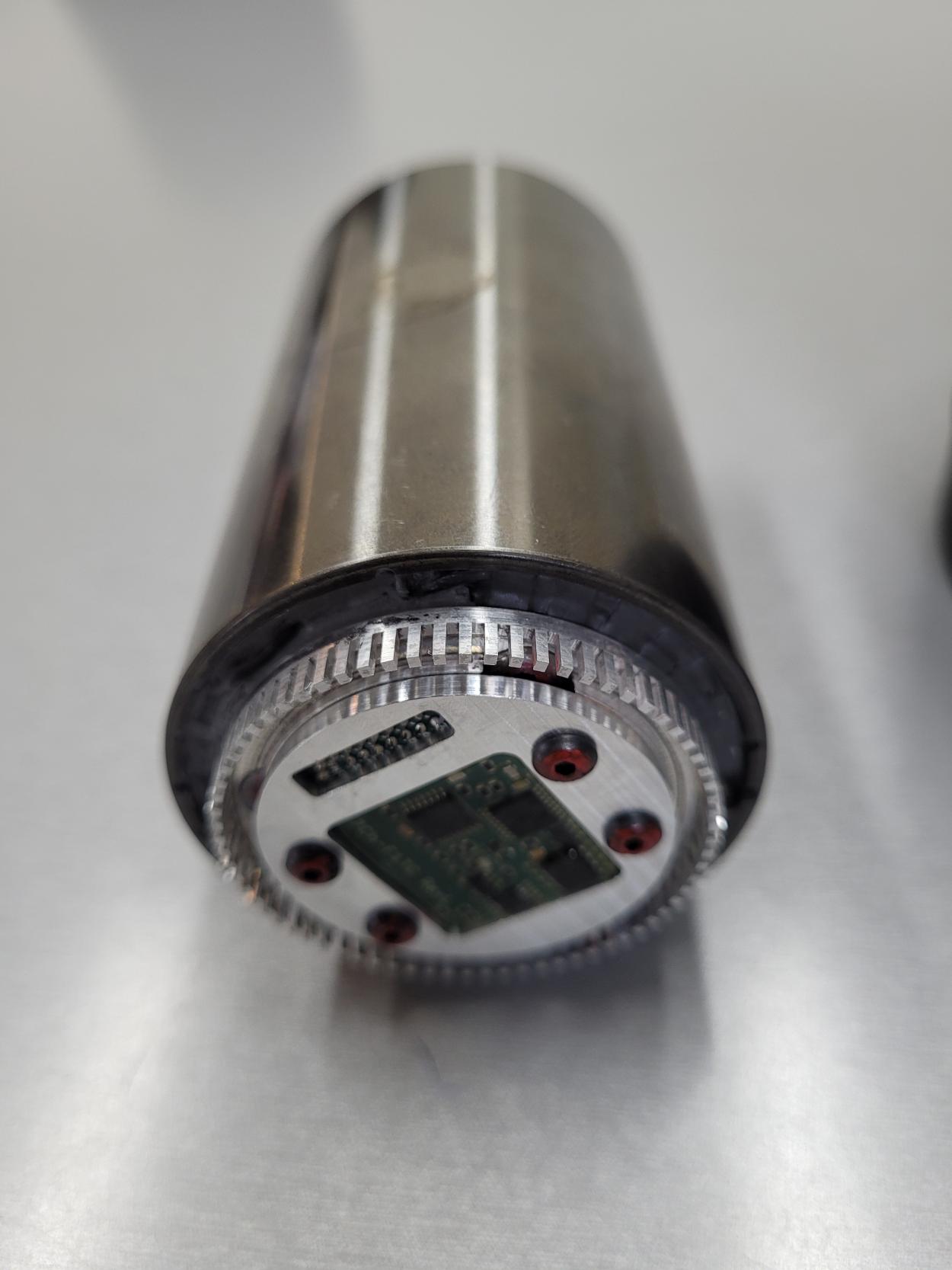

IR Telemetrics Pin Rotation Sensor

IR Telemetrics, Inc., in their repeated effort to bring new measurement technology to their customers, has developed a patented pin rotation sensor designed to measure the rotation of the piston pin in a running engine. This measurement capability gives development engineers a powerful tool to learn how different engine speed and load conditions affect pin rotation.

This transducer consists of a castellated ring devise mounted on the end of the pin. Mounted on the piston is an optical transducer that passes light through the cutouts on the ring and in doing so can determine direction and speed of the pin’s rotation. The rotational data is then transmitted off the moving piston using IRT’s inductively powered Microwave Telemetry System.

This measurement is often taken simultaneously with piston pin temperature, and/or piston temperature. IR Telemetrics has successfully installed two to three different transmitters on a piston to accomplish this, providing temperature data at 15 locations on the piston and 7 locations on the piston pin. Having these temperature measurements transmitted simultaneously with pin rotation helps the engineers understand how the expansion of the pin and piston due to temperature affect the rotation of the pin.

Regardless of the specific details related to rotating machinery, IR Telemetrics can provide you with a custom-built telemetry system to evaluate the critical characteristics of your components rotating in their production environments, to insure they are operating as their design intends them to. Contact us to discuss your project needs!