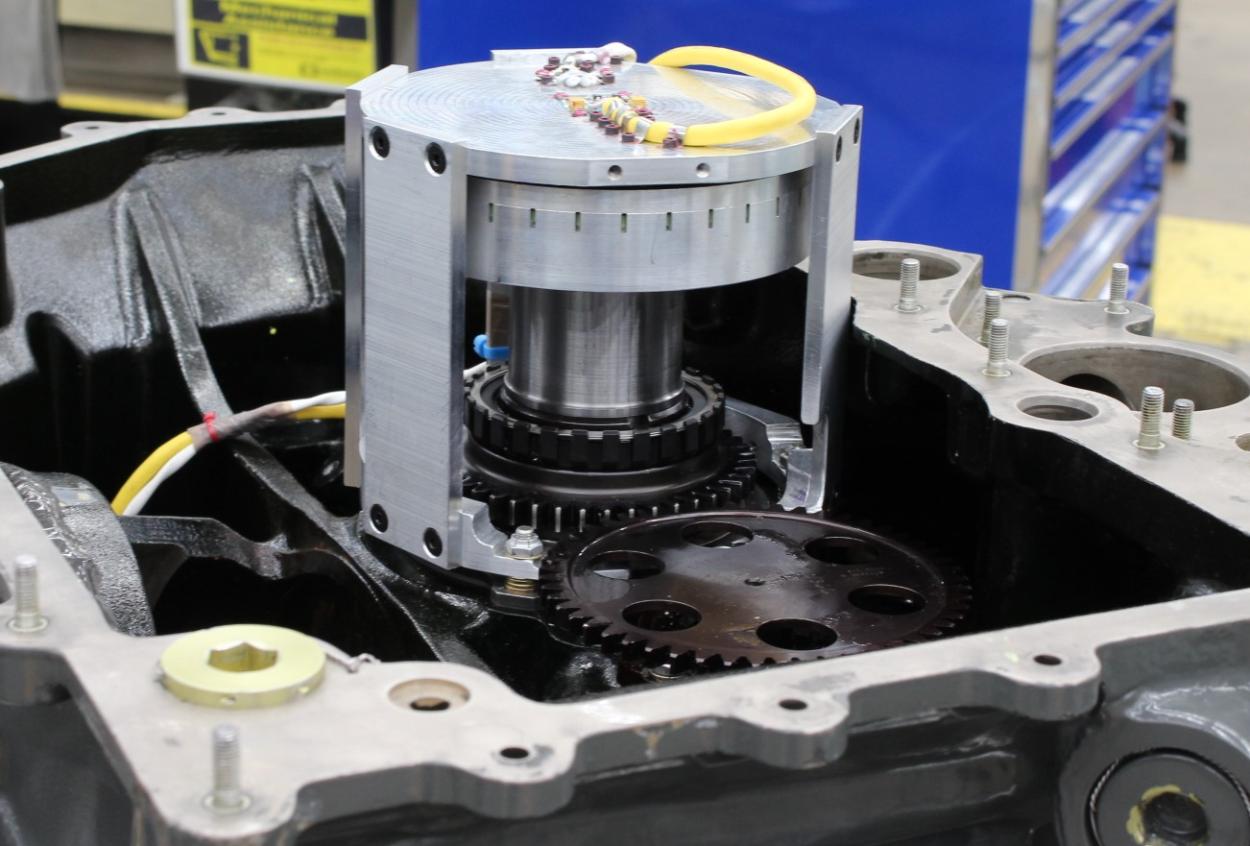

Measuring the relationship between input torque and resulting gear strain in a large gear box.

In the development of complex gear boxes, such as those used on helicopters to drive the rotor, it is critical to understand the torque on the input shaft, and the resulting strains on the gears within the gearbox. In addition, it is critical that the torque and strain measurements be made simultaneously for the input shaft and each gear, and be measured with a high sample rate to capture the true dynamic loading occurring between the gears. Traditionally, slip rings were used in this type of application, but often yielded a noisy signal and required extensive maintenance.

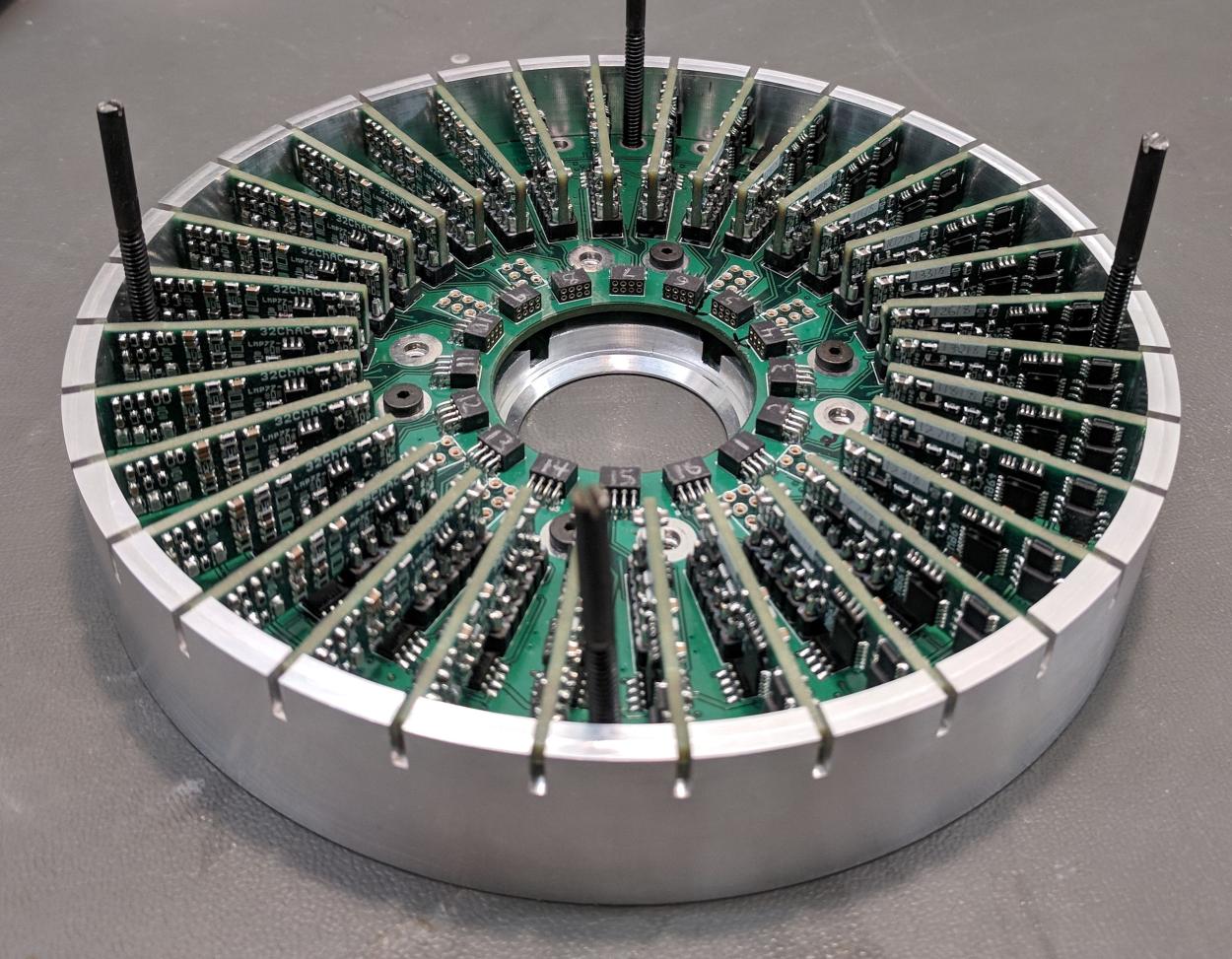

IR Telemetric’s custom wireless 32 channel digital transmitter

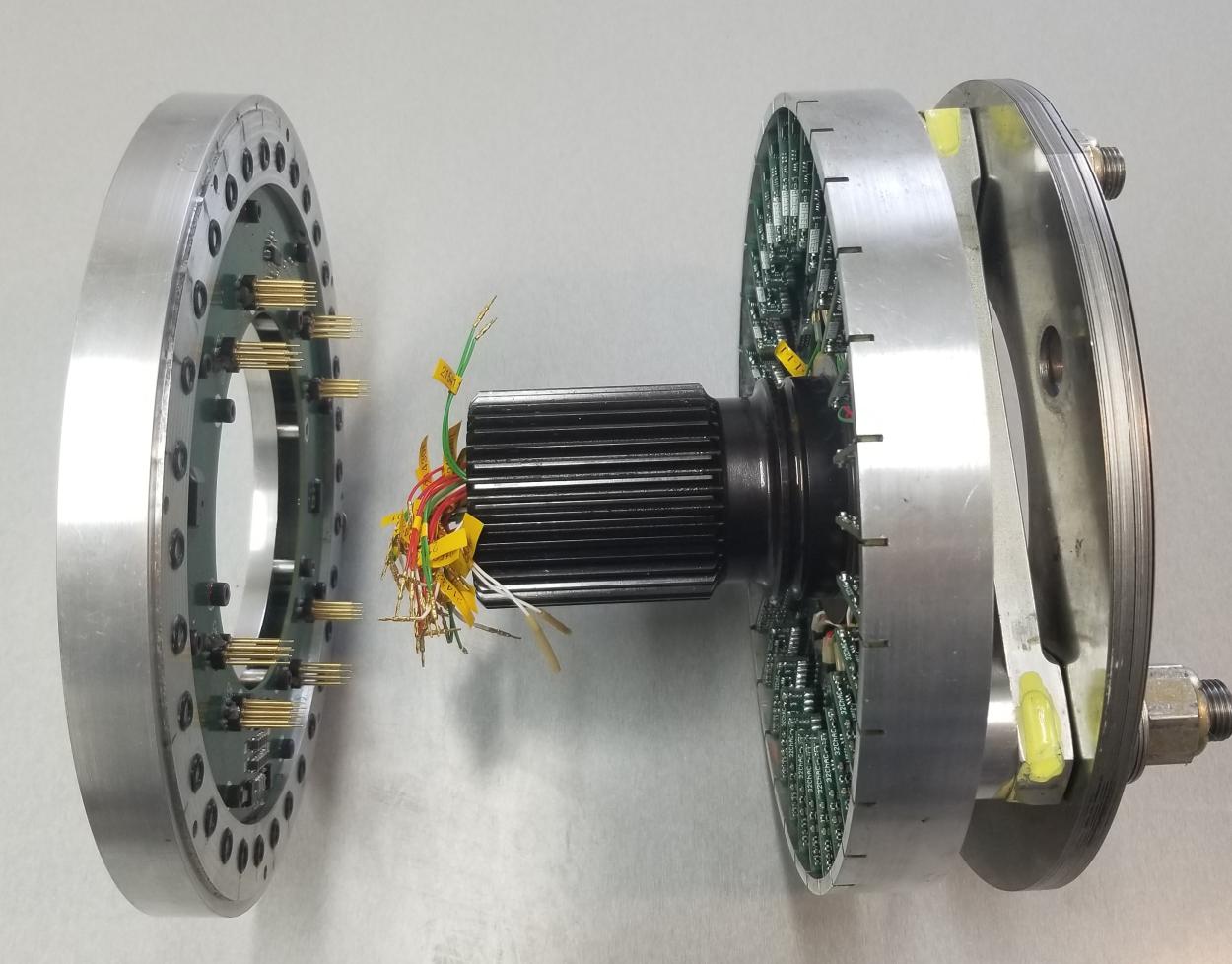

Telemetrics, Inc. has designed several custom wireless measurement systems to replace slip rings. These torque telemetry systems are more reliable and meet the specific requirements of their customers. In this application, a 32-channel digital transmitter was required on an internal gear to measure strains, and another 32-channel digital transmitter was mounted external to the gearbox on the input coupler. The external transmitter measured the input torque, plus strains on a second internal gear which the input coupler was driving through the splined shaft.

Both transmitters were inductively powered and used a pair of close coupled inductive coils (Near field) to transmit and receive data. Data transmission via infrared LEDs (Line of sight) is technology also offered by IRT on these transmitters for end-of-shaft applications. Each channel in the digital transmitters has an individual A/D converter and amplifier. This allows a mix of transducer types like thermocouples, pressure transducers and, in this application, strain gages. This design also allows a transmitter to be reconfigured for a different application. In total, this combination provided 64 channels of strain data, measured simultaneously at 50kHz per channel, with 14-bit resolution.

With long life durability and high rotational speed capability, IR Telemetrics 32 channel digital transmitters provide extended hours of noise free and maintenance free test time compared to a slip ring design.

Contact IR Telemetrics to review your needs in detail and learn more about our guarantee of successful data transfer.