Monitor Crack Propogation During Operation

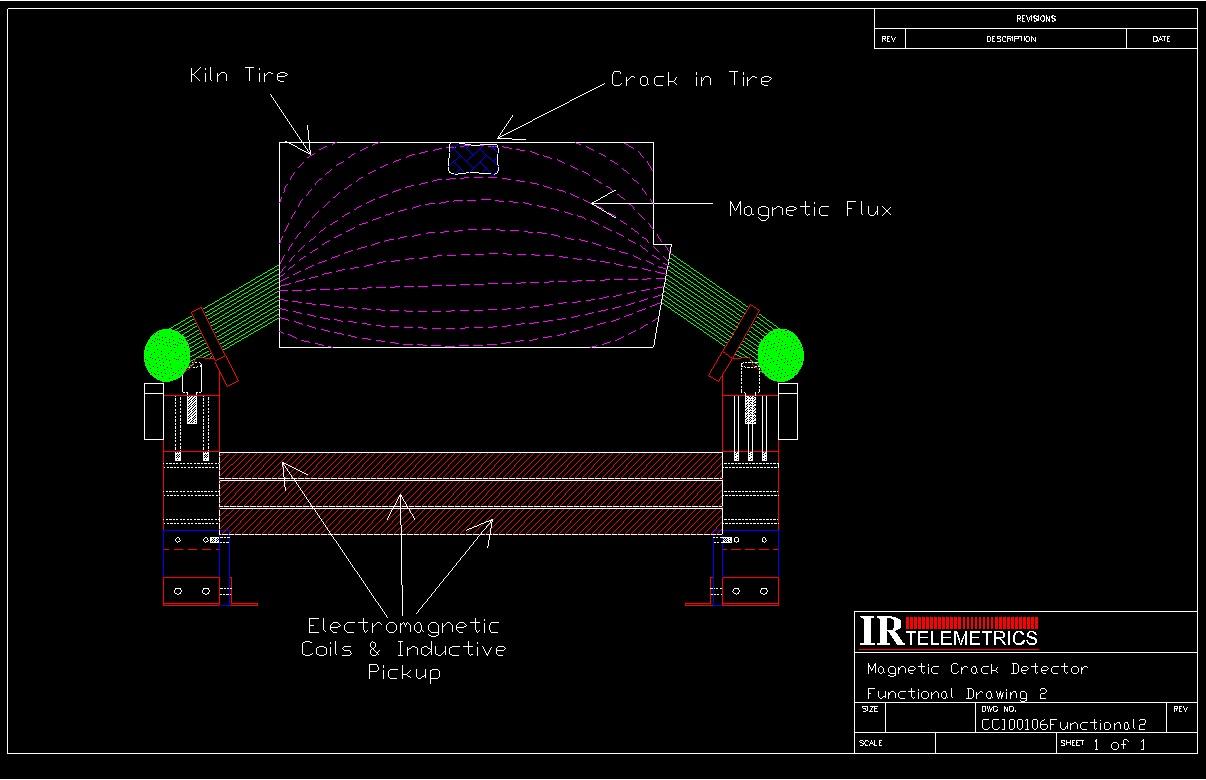

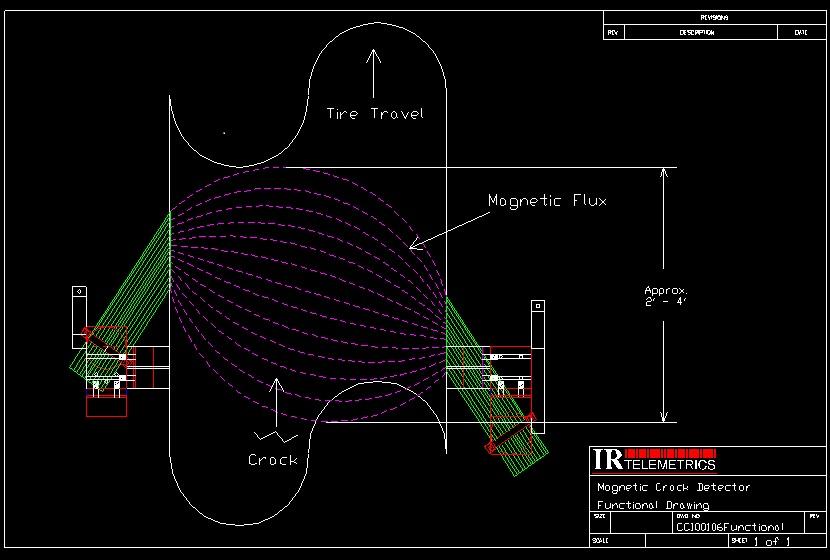

Crack detection in rotary kiln tires can prevent unscheduled maintenance and costly downtime. IRT's crack detection technology utilizes our proprietary electromagnetic sensors to monitor the condition of steel kiln tires during normal operation. This provides not only a baseline of tire condition, but allows our customers to detect crack growth below the surface and schedule maintenance before the crack reaches the critical rolling surface.

The IR Telemetrics' crack detection system provides continuous monitoring of cracks, delaminations or other defects within kiln tires or other large rotating systems. Our proprietary technology generates clear baseline data for a kiln tire and remains in place, scanning for the emergence of cracks or other mechanical signs of fatigue.

Real Time Crack Growth Monitoring

Because it generates realtime data, up-to-the-minute status of an operating system can be checked against the original baseline scans to determine if a crack has been created or a small defect propagated into a potential hazard. Because the IRT Crack Detector can show how a small defect is growing, downtime for welding repair can be scheduled in advance and emergency downtime prevented. The ROI for the IRT Crack Detection System is very short – preventing a single emergency repair offsets the cost of installation.

Investment in our Electromagnetic Crack Detector and ensure predictable maintenance for your kiln tires or other rotating system. To review your needs with an engineering manager, please contact us.

Applications