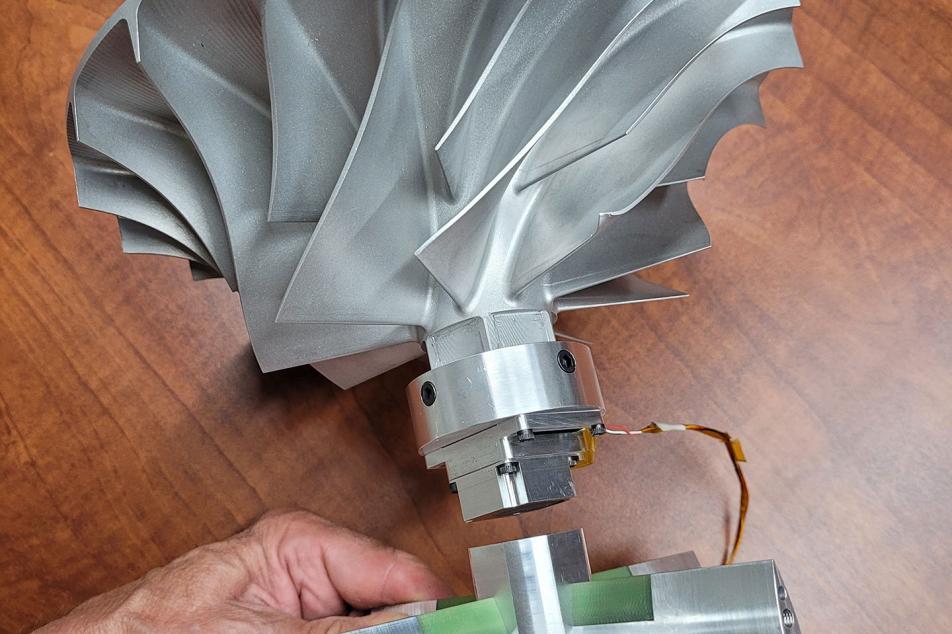

Challenging environments for wireless measurement systems: Diesel Engine Turbo Charger

In the development and validation of engine components, engineers need critical data from rotating and reciprocating components. One example is turbine blade temperatures on a diesel engine turbo charger. This type of application presents many challenges to design and implement a Wireless Measurement System.

IR Telemetrics Temperature Transmitters

In the case of turbine blade temperatures on a turbo charger, special thermocouples, wires, and protective coverings are required on the turbine surface due to the extreme gas temperatures. In the case of this second stage turbo charger on a large locomotive diesel pictured here, special spot-welded super alloy straps and epoxies were used to support and protect the thermocouple wires routed from various locations to the center nose of the turbine. An EDM machine was required for drilling very small holes in the Inconel turbine to route thermocouple wires down the center of the shaft connecting the turbine to the compressor. A tube extending out from the shaft contained a custom-built high-density pin connector to facilitate the thermocouple wire connections to the transmitter, on the compressor, after the compressor was threaded onto the shaft.

Since the inertial loading goes up exponentially in the radial direction, the transmitter size must be limited in order to withstand the high rotational speeds (40,000 RPM). The inductively powered transmitter, mating inductive exciter coil, and antennas must also be designed to minimize restriction and disturbance of the airflow coming into the compressor.

IR Telemetrics accomplished this by designing an aerodynamic “Rocket Shaped” stator with four antennas embedded into the supports. The antennas receive signal from the microwave transmitter and are carried into the Microwave Receiver and Data Acquisition System providing real time turbine blade temperatures at multiple locations.

IR Telemetrics, Inc. specializes in these type of telemetry measurement systems with over 30 years of experience designing, building, and installing custom Telemetry Systems on rotating and reciprocating machinery components operating in harsh environments. Our inductively or battery powered systems that can transmit temperature, pressure, strain, acceleration, motion, proximity, and more. They can survive high temperatures, high G loading, and mechanical strain.

Contact IR Telemetrics to learn more today!